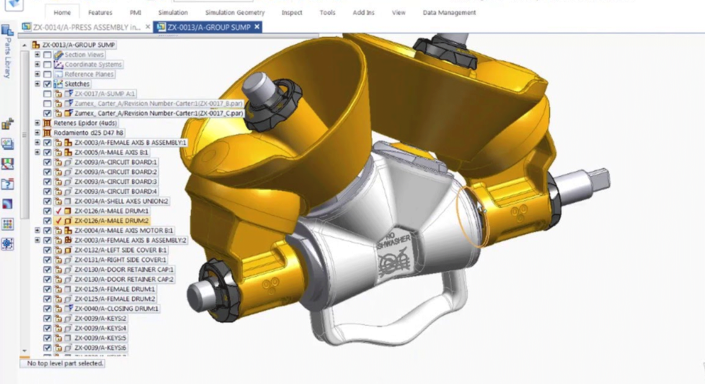

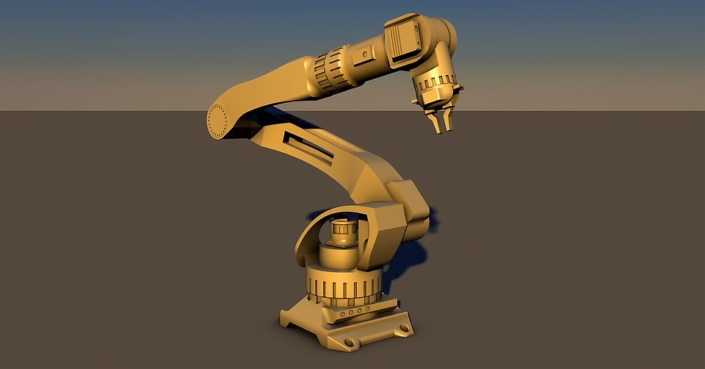

From the first CAD study to the delivery of parts to the customer, technology plays an extremely important role.

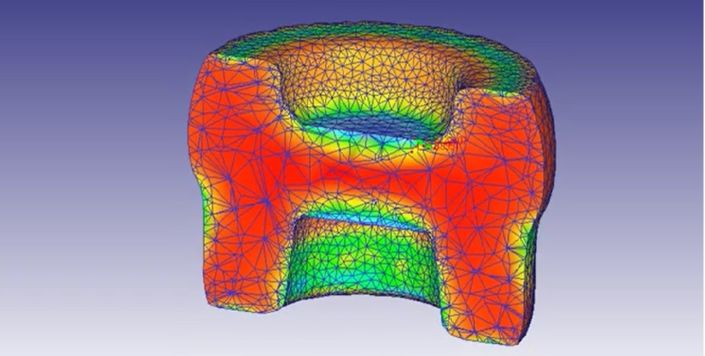

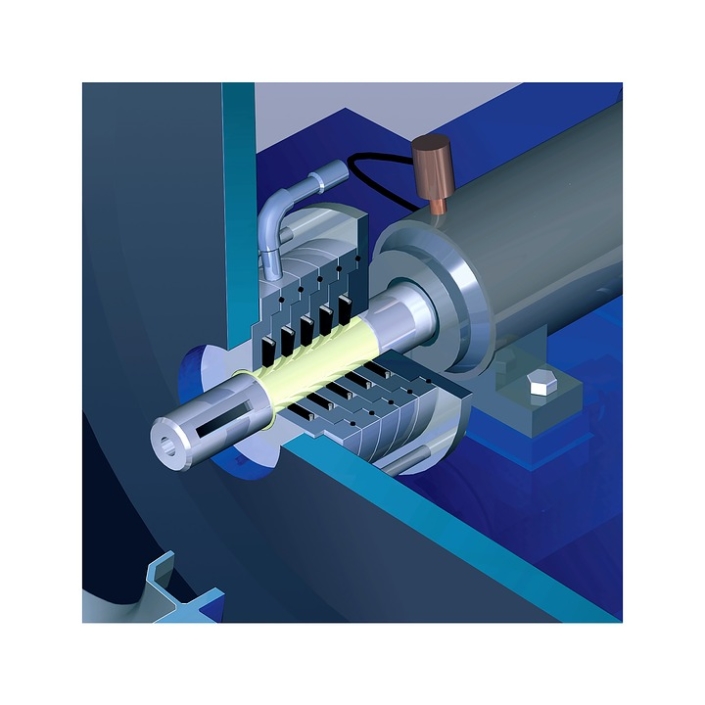

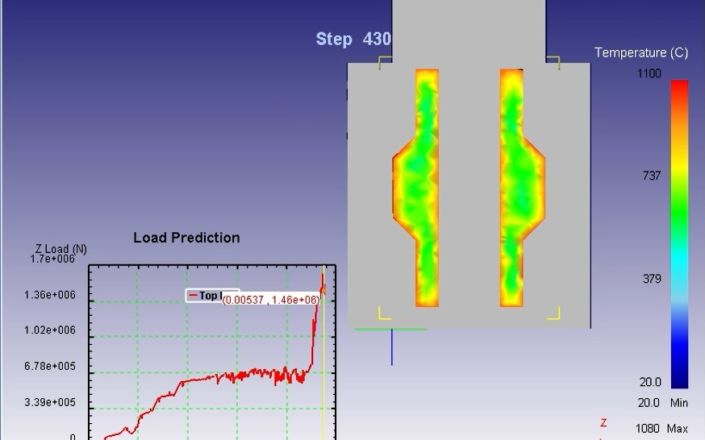

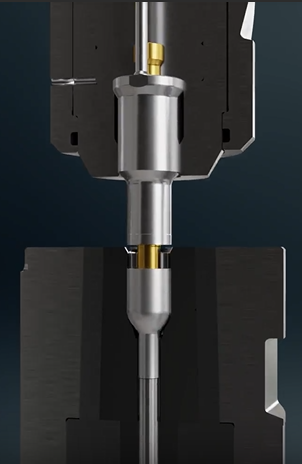

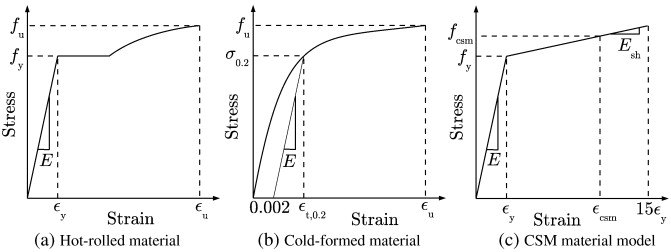

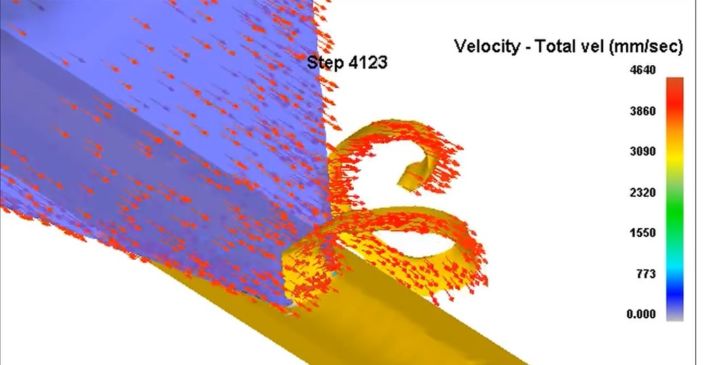

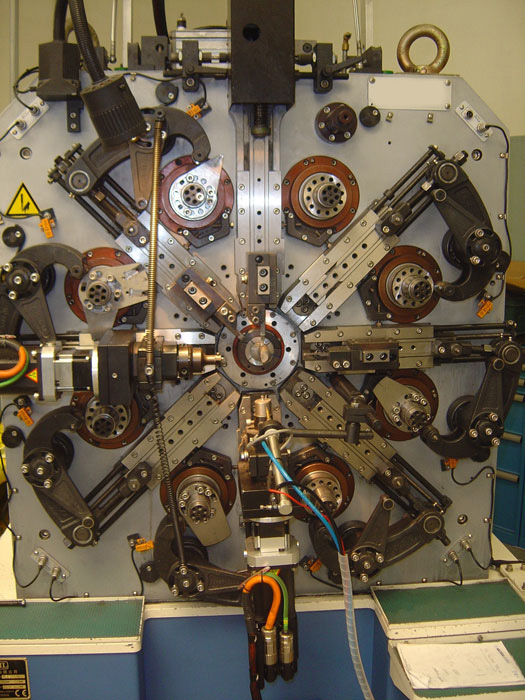

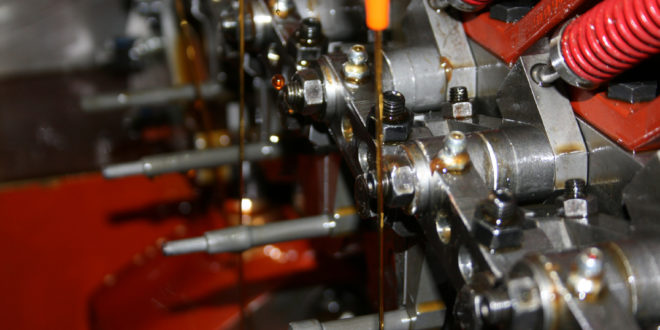

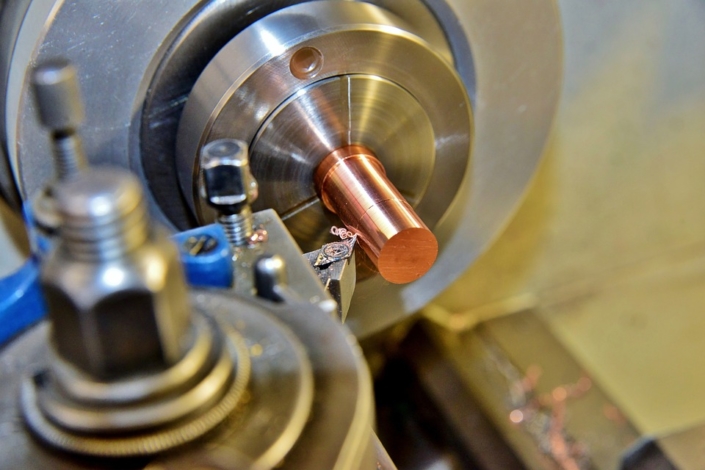

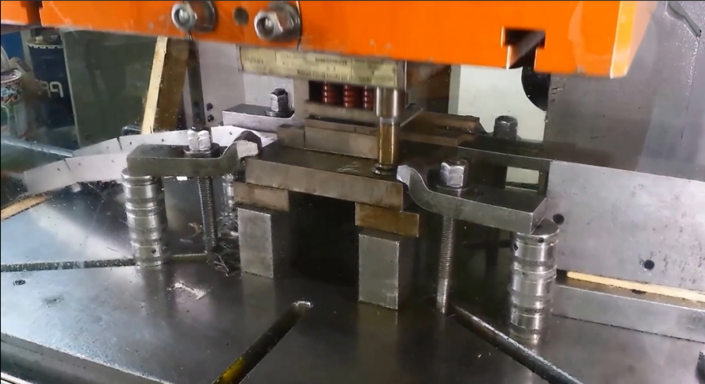

State-of-the-art software such as the FEM simulator used for the studies of plastic deformation processes, on-board machine process monitors, SPC methods for constant containment of cp and cpk values, 4.0 configurations for interconnection and digital measuring instruments – laser – X-ray – eddy currents, are just some of the technological tools used in production and placed on horizontal printing presses (cold and/or semi-solid wire, also in progression), of the vertical (sheet/squares/strips, also in step), of the lathes (Fantines/multi-spindles/CNC), of the laser cutting, of the camera machines, of the molds for Poly casting, spring-former and spring-former coils.

Thermal treatments and antioxidant coatings are also monitored and verified through highly accurate instruments.

3D automatic optical sorters and automated packaging systems complete the picture.

We use the most advanced technologies in the industry in order to obtain, even in Co-Design, direct supplies of components in every printable / turning material, characterized by excellent quality and extremely competitive economic positioning.